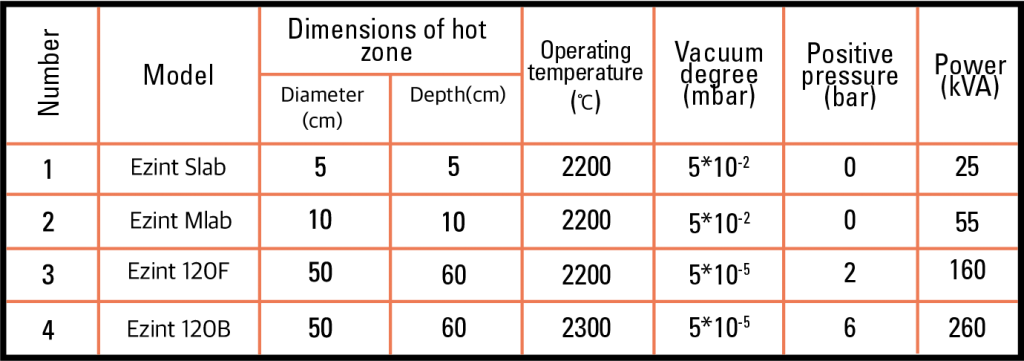

EZINT SERIES

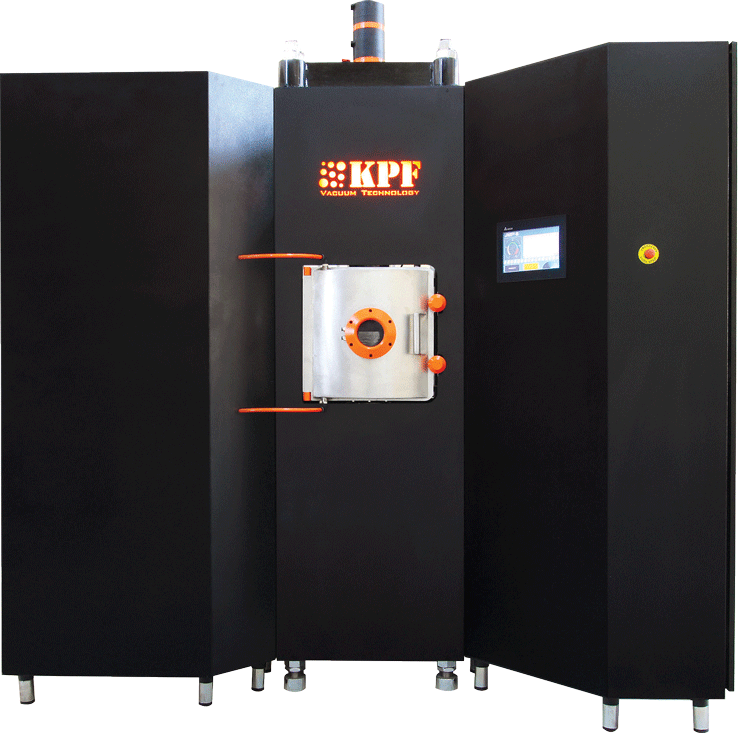

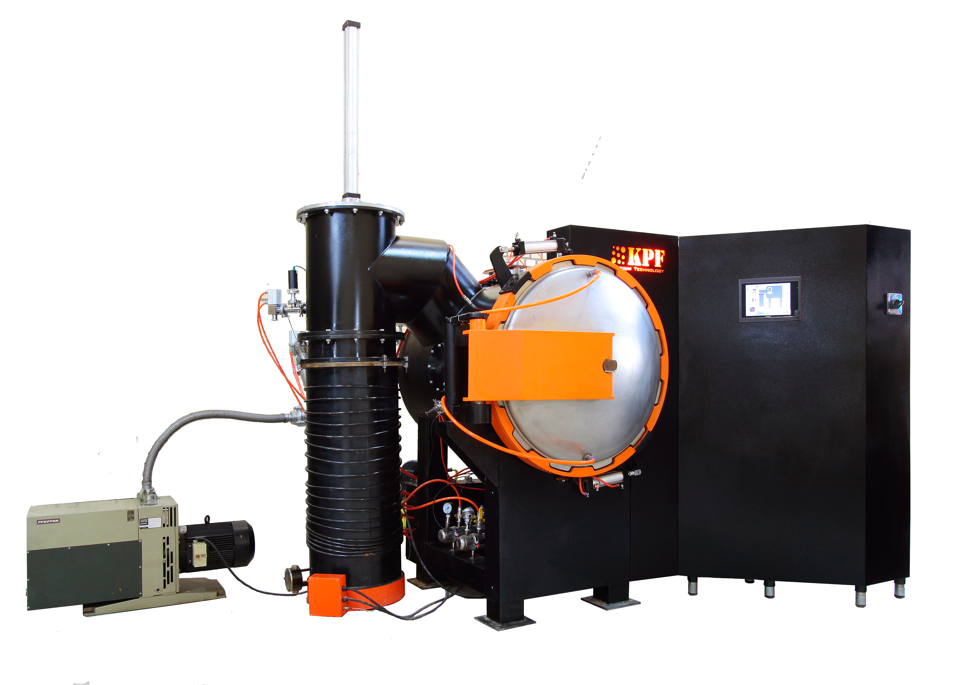

High Temperature-High Vacuum Furnace

Applications

- Sintering wide range of engineering ceramics ( nitrides, carbides, oxides, etc.)

- Brazing

- Carburizing

- Annealing

- Diffusion bonding

- Thermal treatment

- Operating temperature up to 2300

- Vacuum degree: 5*10-5 mbar

- Resistance thermal system and graphite thermal element

- Graphite thermal insulation with minimal energy dissipation

- Double-walled water-cooled stainless steel chamber

- Door self-locked system for withstanding to positive pressure (autoclave)

- The possibility of gas injection up to 6 bar pressure

- Rotary and diffusion vacuum pumps along with cold trap

- High-current power supply with continuous control connected to central control system

- Temperature measurement by dynamic thermocouple and pyrometer in combination

- Ability to install quenching system

- Fully automatic control of system with programmable central control system

- Equipped to various sensors and necessary protections

- Commanding and monitoring with touchscreen 10 inch TFT

- Ability to draw different graphs and data storage