Skip to content

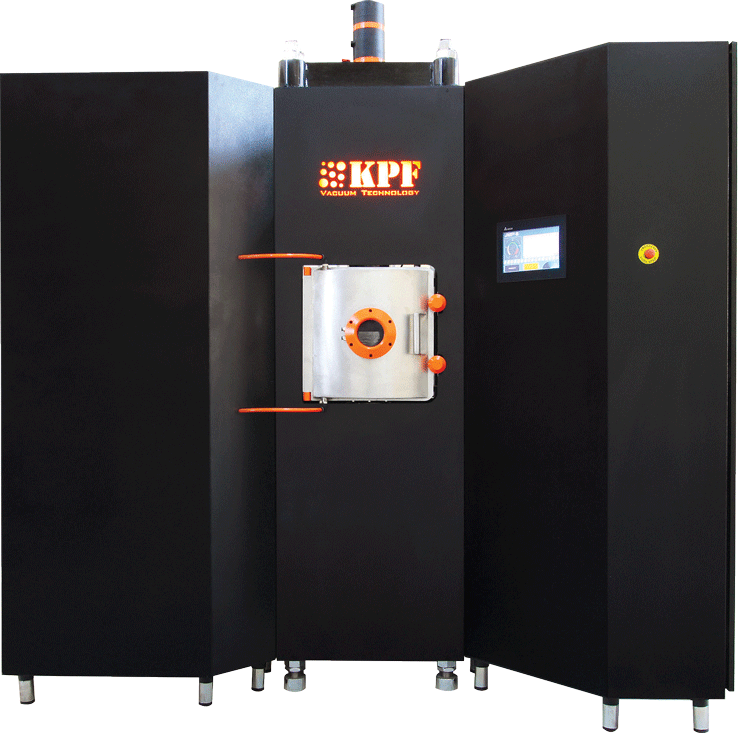

Vacuum Hot Press (HP)

Applications

- Hot Compacting of oxides, nitrides, borides, carbides, sulfides and mixtures thereof to near theoretical densities

- Sintering of nanostructure metallic and ceramic powders

- Sintering of amorphous powders

- Diffusion bonding

- Operating temperature up to 1600

![]()

- Vacuum degree: 5*10-2 mbar

- Argon/Nitrogen gas entry (and the other gasses, if needed)

- Force application system up to 10 ton

- Adjustable punch speed and hydraulic force from 0 to 10 ton

- Punch position control system by accuracy of 100 μm

- Punch position instantaneous measurement during sintering

- Double-walled water-cooled stainless steel chamber

- equipped to self-locked door and sensor and seeing window

- Easy accessibility for placing and fixing the mold

- Temperature measurement by R-type flexible thermocouple

- High-frequency induction heating system

- Increasing heating rate up to 300

![]() /min

/min - Ability to set all sintering parameters

- Fully automatic control of system with programmable central controller and all necessary safeties

- Commanding and monitoring with touchscreen 10 inch TFT

- Cooling system to protect the sealing and packing at elevated temperatures

/min