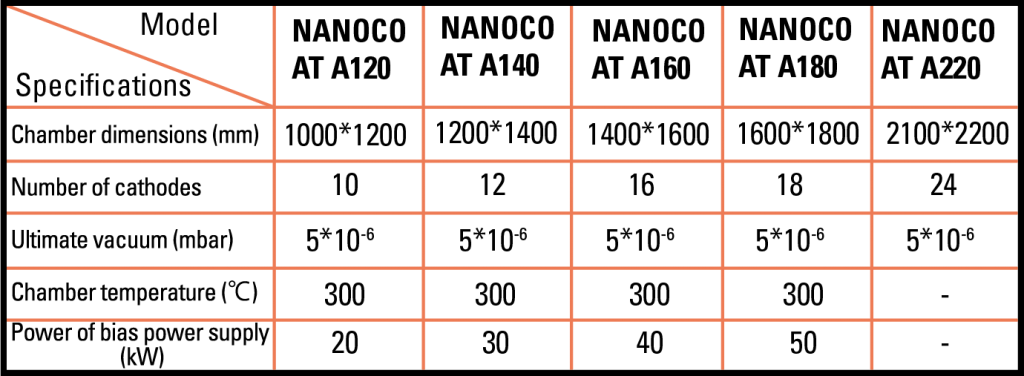

NANOCOAT SERIES

Cathodic arc vacuum coating system (Arc-PVD)

The Physical Vapor Deposition (PVD) method means the vapor deposition of a substance in a vacuum environment on the object. PVD are done in a variety of ways. One of these methods is evaporation with the help of a cathodic arc, which has many applications in creating decorative layers with various colors and high durability.

Applications

- Bathroom and kitchen sanitary faucets & accessories

- Kitchen appliances

- Cosmetic appliances

- Ceramic & mosaic tiles

- Car rings

- Door and window handles

- Furniture

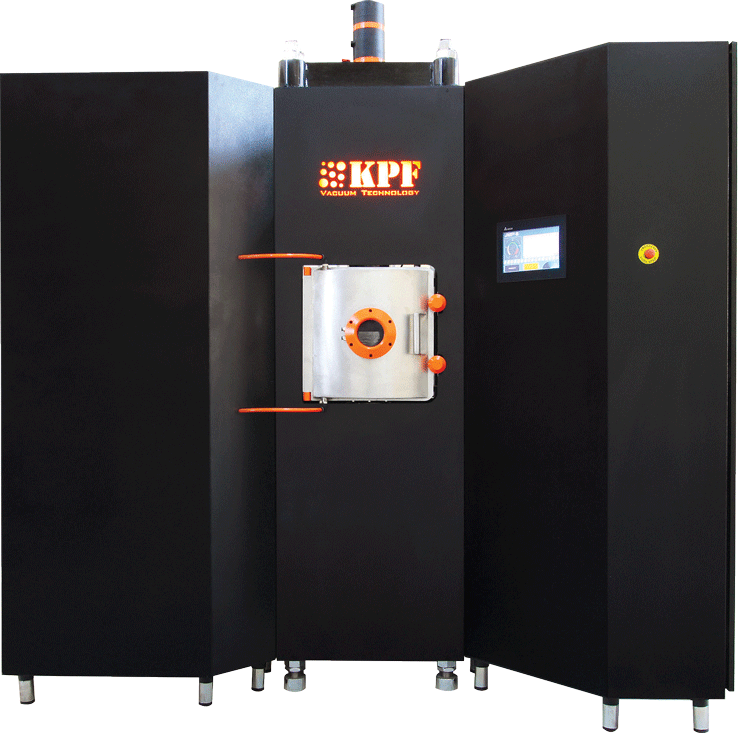

- Double-walled vacuum chamber

- Cathodic arc evaporation source with 4 inch target and target optimal consumption

- 4 mass flow controller from trusty American brand

- Equipped with plasma cleaning system

- Equipped with high-bias voltage system for greater adhesion of the layer

- Equipped substrate heating system and control temperature in vacuum chamber up to 300 °C

- High vacuum system with rotary, roots and diffusion pumps and diffusion holding pump to prevent energy dissipation

- Vacuum measurement system from trusty European brands

- Automatic control system

- Commanding and monitoring with touchscreen 10 inch TFT with the possibility of storing all parameters to detect operator errors

- Integrated structure with easy installation, repair and maintenance