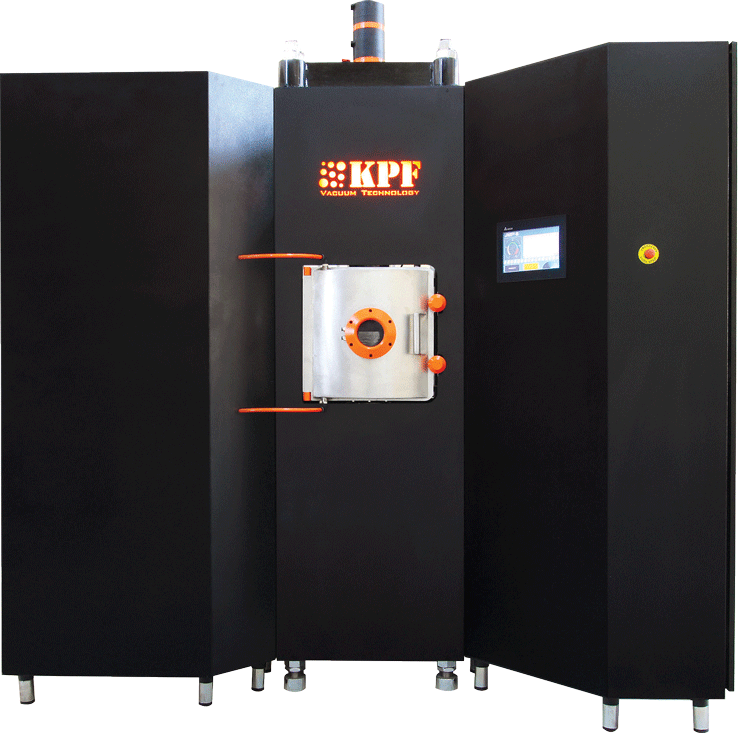

KCIP SERIES

Cold Isostatic Press (CIP)

Cold Isostatic Press (CIP) is a materials processing technique in which high pressure is applied to metal powder in a sealed elastomer container shaped for the application. The powder is converted from a loose aggregate in a partially dense compact that has sufficient green strength to permit careful handling and transfer to the following process operation

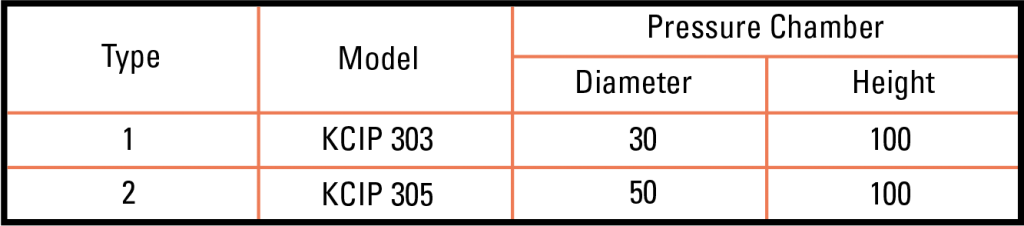

- Pressure chamber dimensions according to the table

- High strength steel chamber, designed with American Standard

- Final pressure of 300 MPa (3000 bar)

- Pressure control system and adjustable pressure from 0 to 300 MPa

- Touch screen with pressure-time charting capabilities and data storage

- Automatic rotary protection chamber to lock the pressure chamber and protect the user

- Special basket for loading and unloading of components

- Cold comprehensive consolidation of ceramic, metallic and combinatory powders