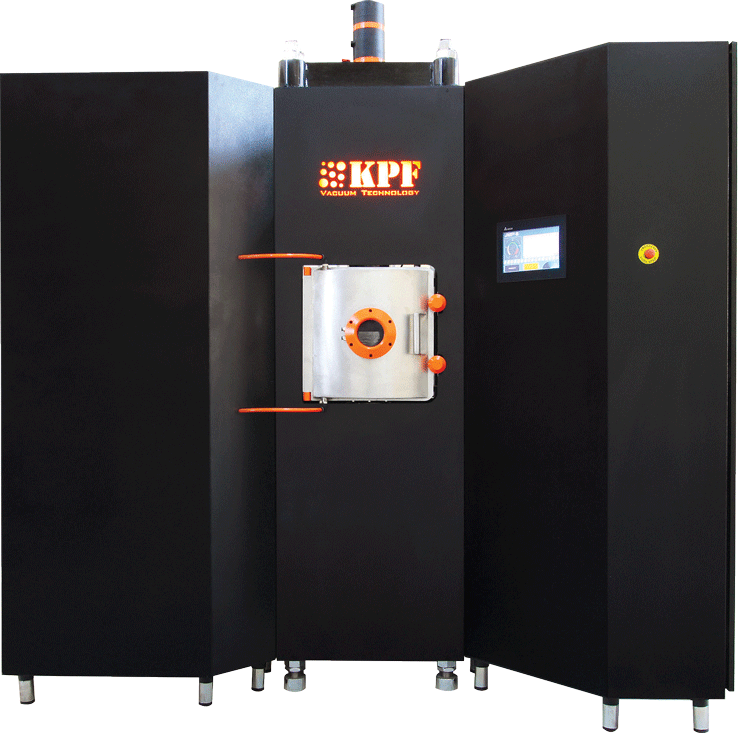

B CAST 350

Vacuum melting and casting for single crystals, directional crystals and polycrystals

Applications

- Ni based super alloys gas turbine blades

- Impeller of supercharger

- Super alloy valves

- Fuel and hot gas nozzles

- Semiconductors and piezoelectric materials

- Synthetic gemstone

- Two vacuum chambers with separate vacuuming system

- Melting capacity up to 20 kg of super alloy by induction furnace

- Furnace with two heating zones with a diameter of 35 cm and a height of 50 cm

- Independent and accurate temperature control of each area of the furnace

- Vibration-free movement of the mold lifting system with the ability to adjust the speed in the range of 1 meter in 3 minutes to 1 meter in 25 hours

- Ability to quickly convert single crystal system into polycrystalline (two separate doors in the upper chamber)

- Fully automatic sampling system, slag breaker, sample addition and instantaneous melt temperature measurement

- Ability to add different sensors on the cold plate (mold lifter)

- Automatic PLC system with the ability to control all parameters and detect all errors

- Commanding and monitoring with touchscreen

- Electric and intelligent rotation melting ladle system with easy control

- Integrated ergonomic structure with easy portability